BASIC INFO

OEM No.:0075

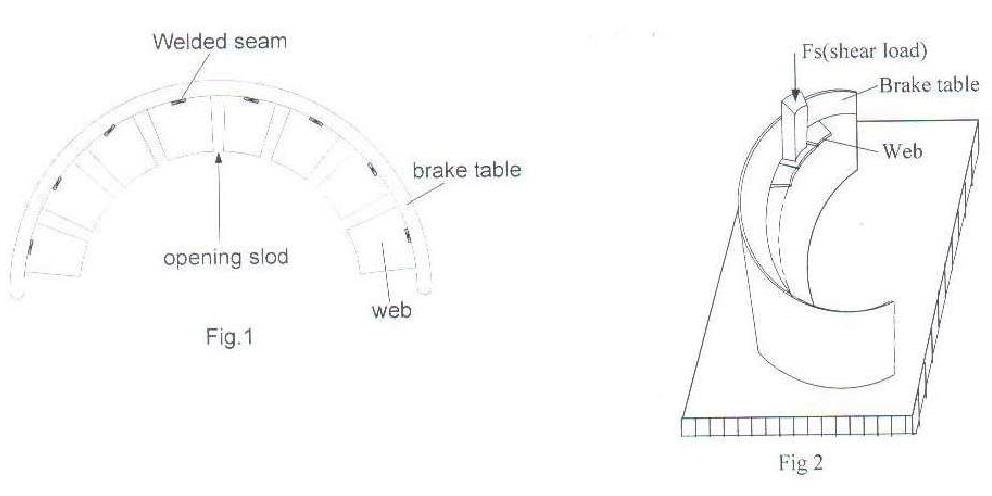

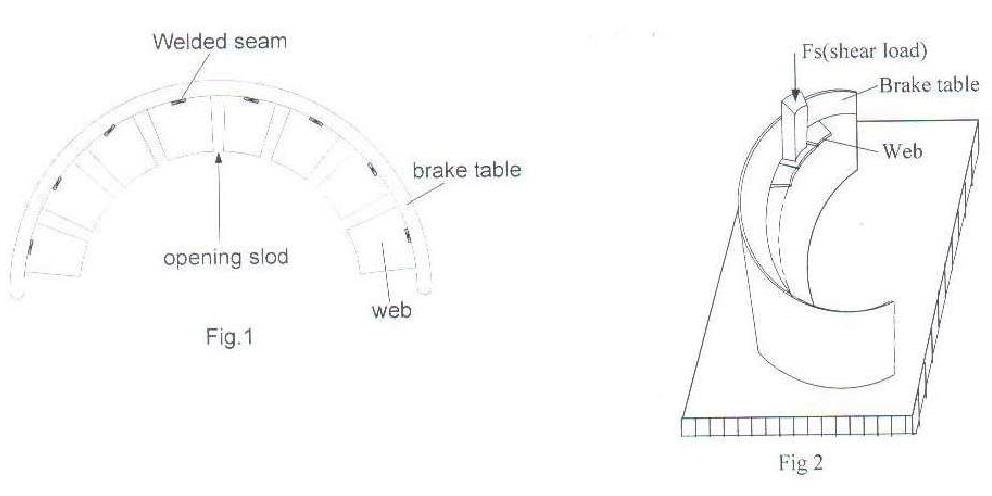

A drum brake is a brake in which brake shoes with lining (friction material) attached to them are pushed by hydraulic pistons against the inner surface of a drum rotating together with the axle. This generates friction, which converts kinetic energy into heat and slows or stops the drum and the attached wheel. Drum rotation helps to press the shoes and the lining against the drum with more force, offering superior braking force in comparison with disc brakes.

Brake shoe is one of the most important part in the drum brake system .

FMSI :GG83

Material:Q235

Surface treatment: electrophoresis or powder coating

Welding method : MIG

Sheet metal thickness :6mm

Heat treatment : 35 HRC

Mass:

Packaging : plywood pallet with stretch film

Stamping mark : customized logo or numbers on Web .

Reline cycle : 4 times at least

Quality inspection

Inspect point ,generally inspection (drawing dimensions, web perpendicularity and parallelism, table radian.)

welding strength ( breaking test )

Quality insurance

Radian : reshape by 1000t Hydraulic Press machine after welding . radian precision: gap between lining and table <0.3mm

Web perpendicularity and parallelism: use a well-made wielding jig to hold the web part in position before automatic welding .

Concentricity of web R end: boring in the jig after welding .

Powder coating quality : coating thickness inspection instrument, manual scratch testing for adhesion, static spray testing for anti-corrosion performance .

Rivet material CH1T, zinc surface .

Brake lining , GG83

Standard : 23K

Material : No metal or Half metal non-asbestos

Quality level:FF, GG

Features:

1) Stable Friction Coefficient

2) Heat-resistant: Less fading and heat resistant up to 400°C

3) Abrasion resistance

4) Long Service life: normally 60000km

5) Low noise and dustproof

6) Environmental friendly

brake shoe Hardware kit

Material: 45#, 65Mn,

Hardness : 45-55 HRC

Surface treatment: Zinc

A drum brake is a brake in which brake shoes with lining (friction material) attached to them are pushed by hydraulic pistons against the inner surface of a drum rotating together with the axle. This generates friction, which converts kinetic energy into heat and slows or stops the drum and the attached wheel. Drum rotation helps to press the shoes and the lining against the drum with more force, offering superior braking force in comparison with disc brakes.

Brake shoe is one of the most important part in the drum brake system .